ITER: Augmented Reality at the Heart of the World’s Largest Fusion Project

- Key challenge: Provide on-site supervision teams with digital tools that deliver real added value.

Table of Contents

Intergovernmental organization

Nuclear

Tokamak

Executive Summary

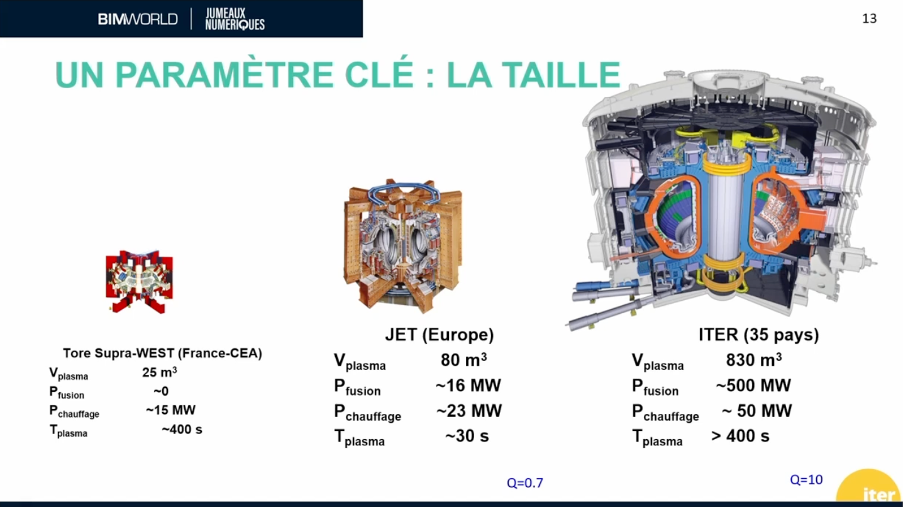

ITER is an international scientific project bringing together 35 countries with the objective of demonstrating the technological feasibility of fusion energy for peaceful purposes.

At the heart of this ambitious program is the construction of a tokamak, an experimental reactor 30 meters high, 30 meters in diameter, and weighing 23,000 tons, designed to prove that fusion can produce more energy than it consumes and pave the way for industrial-scale deployment of this technology.

To achieve this goal, ITER relies on augmented reality to ensure the accurate positioning and compliance of systems supporting the machine’s operation. Thanks to this technology, teams can visualize, verify, and validate the installation of system components on-site, making ITER not only the most advanced fusion project in terms of technology, but also in its construction processes.

The Challenge

Estimated at nearly €25 billion and supported by 35 countries, the ITER project has faced several technical challenges during construction. In 2022, the first sector, one of the nine forming the vacuum chamber, along with two toroidal magnets, was assembled. However, multiple non-conformities were detected: dimensional deviations at vacuum chamber interfaces, as well as corrosion in the cooling circuit of the thermal shields.

The complete replacement of the 23 km-long cooling circuit is scheduled for mid-April 2025. This operation is costly in both time and resources, but essential to ensure long-term reliable operation of the machine.

Faced with these challenges, Lucas Scherrer, Head of As-Built 3D Digital Model Configuration and New Technologies, sought an innovative solution to:

- Reduce communication barriers between site and office while maintaining precise construction control

- Anticipate interferences and avoid new clashes before they occur on-site

- Reduce rework costs by identifying deviations as early as possible

- Improve on-site efficiency

The Solution & Implementation

To meet the needs of the ITER construction site, the team selected GAMMA AR, an augmented reality application for BIM model visualization, capable of handling highly complex technical elements in a constrained environment. The use of tablets and smartphones quickly emerged as the best option, enabling smooth adoption by on-site teams.

Reference 3D models, originally created in CATIA, Enovia, and AVEVA, are now centralized on a neutral platform via Navisworks, enabling deployment in GAMMA AR. The models are easily accessible in the field, even offline, in areas without Wi-Fi coverage.

IT-configured iPad Pros were provided to on-site users as part of the ITER project, giving full access to BIM visualization, verification, and data management directly on the construction site.

In addition, bidirectional synchronization of component information and BCF files, enabled through direct integration with Autodesk Construction Cloud (ACC), ensures continuity of information between site and office, improving collaboration and traceability of interventions.

The Results

“Before, we were still working with paper and 2D drawings: we went on site, took notes, printed PowerPoint slides… and then had to find photos on our phones. Everyone was losing time,” Lucas explains. “With GAMMA AR, data management and on-site component identification are much smoother. We gain efficiency, and above all, we save time.”

Thanks to GAMMA AR, ITER teams now have a mobile technical support tool adapted to their working environment. Supervisors have the reference 3D model at their fingertips to verify installations and check compliance against the planned design. This allows them to detect deviations at the earliest possible stage and have them corrected quickly at reduced cost.

Potential clashes can be anticipated directly on-site, while verification of civil engineering openings before installation is made easier. The system also enables rapid identification of components (pre-embedded plates, in-line components, etc.), ensuring better traceability and faster response to issues encountered on site.

Result: significant reduction in time spent on daily tasks, and smoother coordination between site and office, further amplified by the large number of collaborators present on-site. In addition, faster detection of deviations leads to quicker resolution, drastically reducing rework costs.

Conclusion

The adoption of GAMMA AR within the ITER project perfectly illustrates how augmented reality can support the success of a construction site of exceptional scientific scale. By integrating the BIM model directly into field operations, teams have reduced the gap between office and site, anticipated non-conformities, accelerated decision-making, and lowered rework costs.

Beyond time and accuracy gains, this implementation demonstrates the potential of augmented reality as a coordination and quality-control tool in highly technical environments.

With GAMMA AR, ITER confirms that digitalizing field operations is a key step in advancing major engineering projects and supporting the scientific breakthroughs of tomorrow.

Read more customers success stories

Batson Cook Streamlines Hospital MEP Coordination with AR Technology

Before the Wall Closes: How AR is Raising the Bar in Pharma Construction

Innovating Bridge Inspections with BIM and GAMMA AR for Safer Infrastructure Management