Customer story

How Goldbeck reduced time spent on QA/QC by 80% and saved up to $135,000 per week

This user story explores how GAMMA AR helped Goldbeck to improve project quality and profitability.

About the GC Goldbeck

In the vibrant old German city of Bielefeld, Goldbeck GmbH, a brainchild of Ortwin Goldbeck, began its remarkable journey in 1969. Starting with humble roots, this visionary venture has flourished into a beacon of construction innovation, with a workforce of 12,000 and an impressive revenue of 7 billion euros by 2022. Renowned for its unique, systemized construction approach, Goldbeck masterfully blends industrial efficiency with architectural finesse, creating structures that are not just buildings but landmarks of progress and sustainability. At its heart, Goldbeck’s story is a testament to the power of visionary leadership, commitment to sustainability, and the relentless pursuit of excellence in shaping the future of construction.

Misunderstanding of design and bad communication are a major challenge

Despite great optimization throughout the construction process, one thing has shown to be particularly hard to optimize: Human mistakes, in particular those resulting from wrong interpretation of the design intent and associated processes.

This problem leads to rework, higher costs, delays, and reduced quality. In the US alone, rework accounts for 4-6% of overall construction costs and 10% in Europe.

Augmented Reality is the key to improve project quality and profitability

Goldbeck realized that Augmented Reality on the construction site is the most straightforward way to tackle this massive problem and thus chose to deploy GAMMA AR. This solution places 3D CAD and BIM Models in the exact position on the jobsite and visualizes them in full size through Augmented Reality. It runs on phones or tablets, i.e. on hardware that is readily available on construction sites and doesn’t require additional investments to start bringing value. GAMMA AR enables therefore construction managers, superintendents, and foremen to make better and quicker decisions directly on the job site by accessing the design information in the most intuitive way.

GAMMA AR in practice

1 | Using GAMMA AR, superintendents can ensure that the design is executed by the site teams as intended.

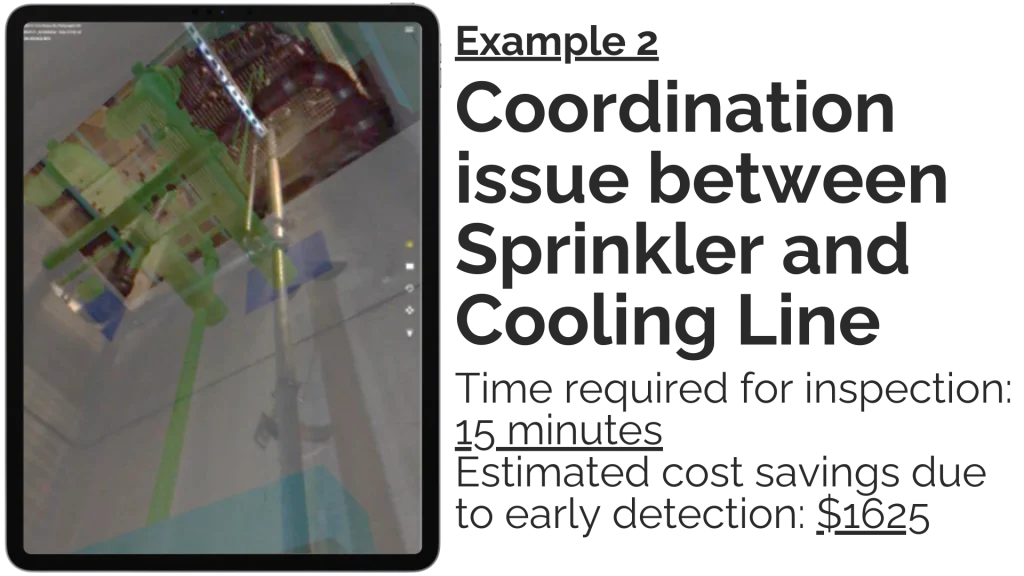

2 | When superintendents do their walkdowns, GAMMA AR assists them in finding deviations early on and discuss possible solutions directly with the teams.

3 | In case any mistakes were detected that cannot be resolved by the site teams, GAMMA AR helps to follow up on issues with object precision.

4 | When the job is done, the App allows the superintendents to track the progress on an object basis and exchange the data with ACC assets to help with assessing the progress of the site in real time.

5 | Finally, using an intuitive visualization of the model speaks more than a thousand words and helps overcoming language barriers:

80%-time savings and cut costs by $1,500 weekly on office building projects

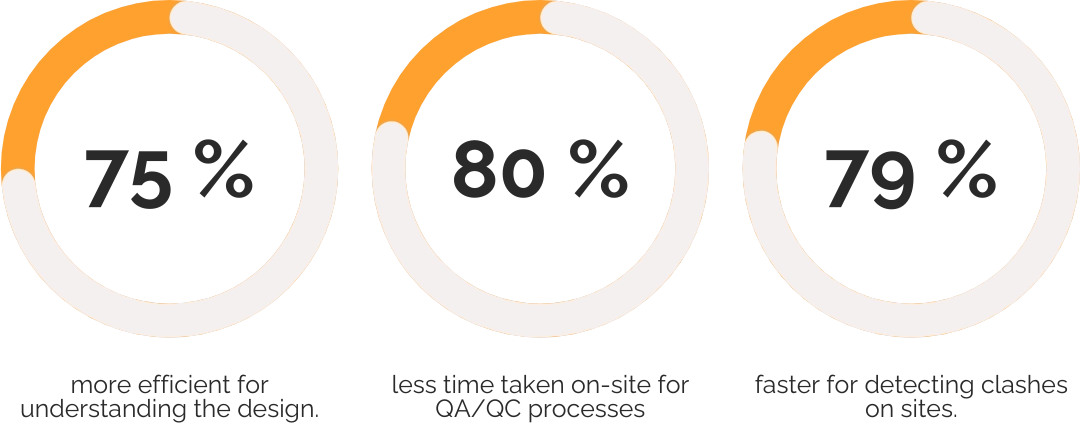

Goldbeck is a data driven company and is very strict in assessing that implemented solutions have a measurable impact on the company’s metrics in terms of quality, costs and time. The company went into extensive testing and collected results from 6 construction projects to determine the effectiveness of GAMMA AR.

The results confirm the envisaged reduction of delays and cost savings that were achieved by bringing the office and jobsite closer together through clear communication and ensuring design interpretation mistakes are avoided on-site.

The reported Goldbeck Site Teams statistics after implementing GAMMA AR speak for themselves:

In total, GAMMA AR helped to save $135,000 per week (1,500$ * 90 jobsites) in their projects and Goldbeck is now implementing GAMMA AR throughout their projects.

With their easy access to AR Technology, we've experienced a significant reduction in rework. Through seamless integration in our processes and a deep understanding of our needs, they've saved us time and resources while setting new industry standards for collaboration.

GAMMA AR isn't just a partner. They're redefining what's possible on a construction site. Their impact is undeniable, and we eagerly anticipate the continued brilliance they'll bring to our projects and the industry.

The team from GAMMA AR is fantastic, and we look forward to many more successful projects."